-

+86-13584422722

+86-13584422722

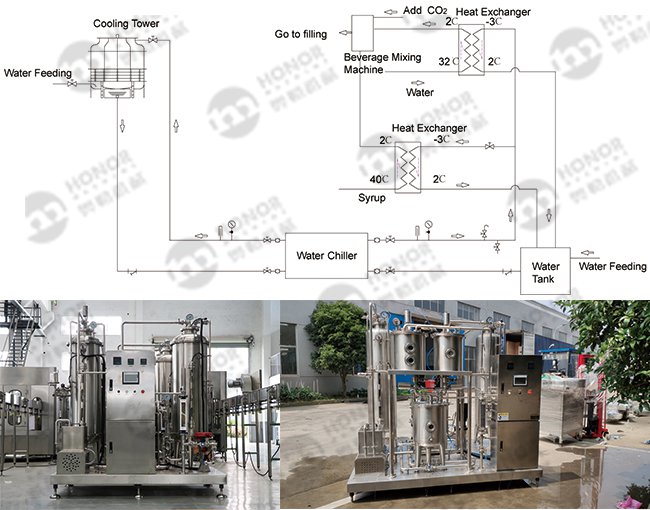

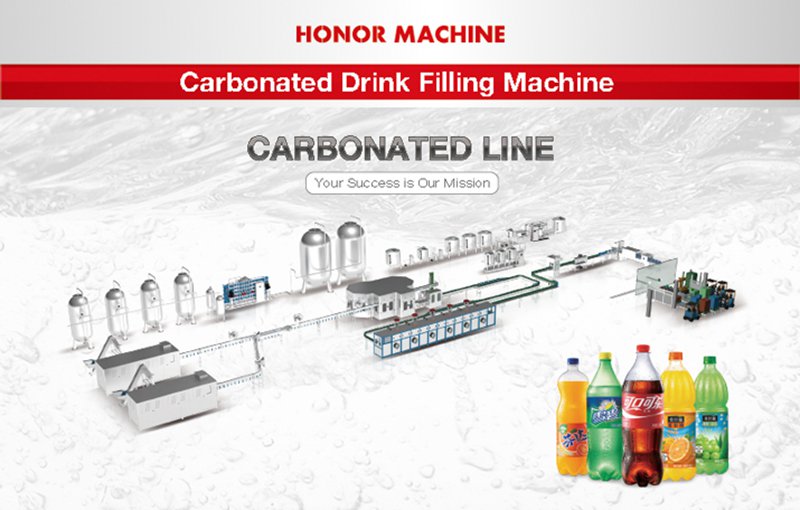

This series of equipment is used in the production of gas-containing beverages, such as Coca-Cola, Sprite, Fanta etc.

| This series of equipment is used in the production of gas-containing beverages, such as Coca-Cola, Sprite, Fanta etc. This machine is washing, filling and capping 3-in-1,This machine is suitable for all kinds of bottle types. It adopts suspension air conveyor. When change the bottle,It only needs to adjust the conveying width, which is more efficient and labor-saving. This machine adopts isobaric filling type, which is faster and more stable. The machine adopts advanced PLC programming control system, and the electrical components adopt internationally renowned brands. The design of the whole machine is scientific and reasonable, with high output and low failure rate. |

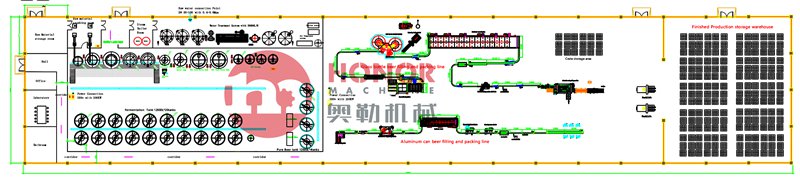

| Technical features: 1)It is adopted that direct connection between air conveyor and inlet starwheel instead of screw and conveyor chains, which is easier for bottle changing. 2)There is no need to adjust the height of equipment through neck holding tech for bottle transportation.And what is only to change some spare parts. 3)High speed filling line is of clamp transferring technology.Bottle shapes are more varied, and the working table inside the machine is more laconic. 4)By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier. 5)Specially designed stainless steel bottle clamp dose not contact the thread parts of the bottle neck, avoiding the second contamination. 6)High speed and large flow filling valve assures the high filling speed and exact fluid level. 7)Parts contact with the liquid are all of excellent stainless steel or food level plastic.The electric system is of international brand and achieves the national food sanitary standard. 8)The bottle-out starwheel is of screwdown shape.When bottle size is changed, there is no need to adjust the transferring chain's height. Flow chart: A)Bottle production line PET Resin --Injection moulding machine -Botlte blowing machine --PET bottle B)Water treatment system Raw water--Pump--Silica sand filter--Carbon filter--Water softner--Reverse Osmosis -UV sterilizer-Ozone generator--Finished water tank C)Filling&Packing part Bottle unscrambler--Air conveyor--Washing,filling,capping 3in1 machine--Light checker--Blow dryer--Dater printer--Lableing machine --Packing machine -Stock |  |

Main parts list:

Item | Parts Name | Brand | Brand |

1 | PLC | SIEMENS | Germany |

2 | Inverter | ||

3 | Touch Screen | ||

4 | Switch | ||

5 | Contactor | ||

6 | Relayer | ||

7 | Solenoid Valve | AIRTAC | Taiwan |

8 | Drive motor | FEITUO | Swiss |

9 | Reducer | CNP | China |

10 | Water Pump | SKF | China |

11 | Main Bearing | AUTONICS | Sweden |

12 | Sensor | AIRTAC | Korea |

13 | Air component | ABB | Taiwan |

Model | DCGF14-12-5 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-12 |

Capacity (500ml/bottle/h) | 1000-3000 | 3000-6000 | 6000-8000 | 8000-10000 | 10000-15000 |

Filling precision | ≤+5mm(liquid level) | ||||

Filling pressure(Mpa) | ≤0.4 | ||||

Filling temperature(℃) | 0-5 | ||||

Total power(kw) | 4.5 | 5 | 6 | 8 | 9.5 |

Weight(kg) | 2400 | 3000 | 4000 | 5800 | 7000 |

Overall dimensions(mm) | 2200*1650*2200 | 2550*1750*2200 | 2880*2000*2200 | 3780*2200*2200 | 4050*2450*2200 |

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

A2:Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

A3:Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

A4:We offer you high quality machines with 2 years guarantee and supply life-long technical support. We Warmly Welcome Customers All Over The World To Our Company If You Have Interests In Our Products. Please Contact Us If You Have Any Problems.You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.