-

+86-13584422722

+86-13584422722

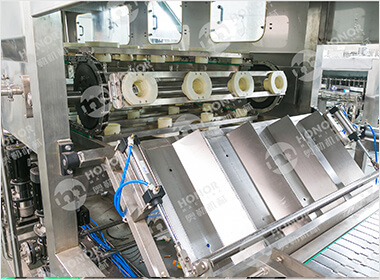

The production line is mainly used for 3-5 gallon barrel drinking water. It consists of three parts: washing(heating water---sterilized water---pure water), filling and sealing.

This production line can be automatically washed, disinfected, filled, capped, counted and output, with complete functions, novel design, high degree of automation, it is a set of machinery, electricity, gas in one of the drinking water barrel equipment.

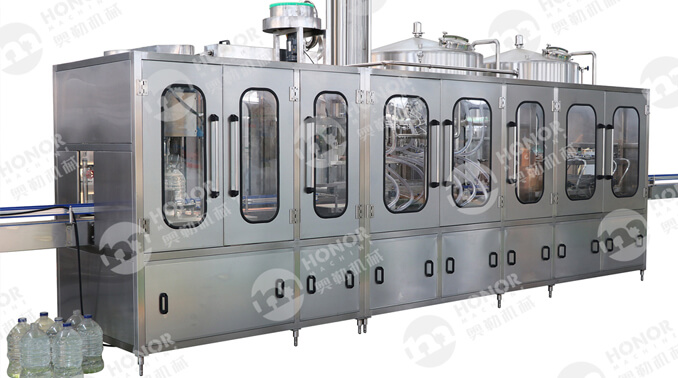

Honor Machine 5 gallon water production line consists of empty bottle transferring, internal bottle brushing, auto de-capper, external bottle brushing, rinsing filling capping, light checker, neck shrinker, bagging, full bottle transferring and pallitizer, enabling full automatic intelligent production. The whole process is strictly controlled, which ensures the complete compliance with customer’s local standards and regulations set up by their Health Department. During filling process, secondary pollution is strictly controlled, which makes it an ultra-clean production line. It’s a most ideal, acknowledged and reliable automatic gallon water production line for companies and factories. This line is mainly used for filling pure water or mineral water of 3 & 5 gallon bottle.

It can apply to fill natural spring water, purified water, carbonated water, flavored water into plastic bottle by changing few spare parts.

Automatic water filling machine adopts Rinsing / Filling / Capping 3-in-1 technology, PLC control, touch screen, it is mainly made of SUS304/ SUS316.

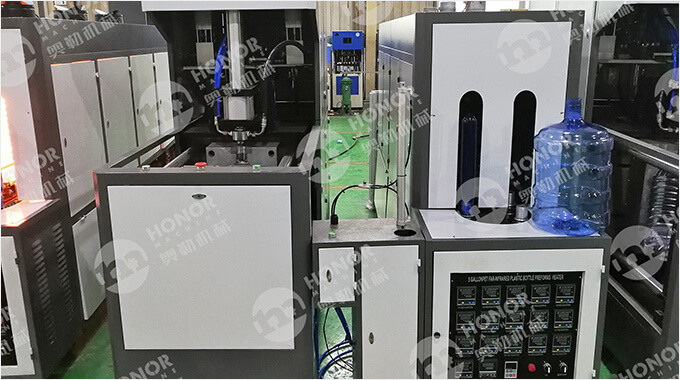

We can provide complete beverage ideal solution - blowing. filling. packing for PET bottle.

It can fill 10-20L bottle size, capacity is 60-1200 bottles per hour.

Pivotal electrical parts use Mitsubishi, OMRON, and SIEMENS.

Filling accuracy is more or less than 1%.

Linear type small capacity water production line

Rotary type water production line

3-10L water filling production line

This production line including automatic washing,filling and capping part.

The line is made of high quality stainless steel, with advanced technology,Stable production and simple operation.

This line can do water, juice and carbonated drink etc...

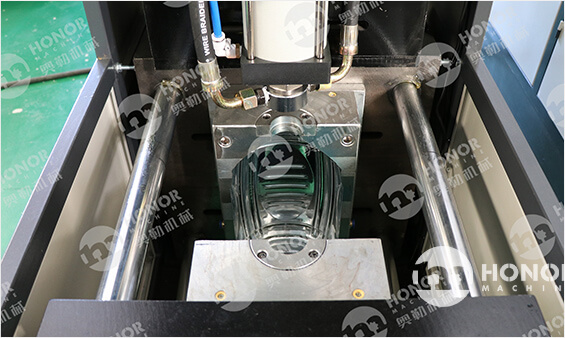

This production line is an integrated device for cleaning, filling and sealing.

This line adopts hanging type air conveyor to make change bottle model more convenient, faster and cleaner.

This line main machine adopts advanced PLC control technology, the key electric elements adopt international famous products or according to customer's customized.

It can apply to fill natural spring water, purified water, carbonated water, flavored water into PET bottle by changing few spare parts.

It suitable for 3-10L plastic or glass bottle.

Automatic water filling machine adopts Rinsing / Filling / Capping 3-in-1 technology, PLC control, touch screen, it is majnly made of SUS304/ SUS316.

Honor Machine provides personalized customization services, for the unique characteristics of customers, specially designed LOGO for customers, to meet the diversified needs of customers.