-

+86-13584422722

+86-13584422722

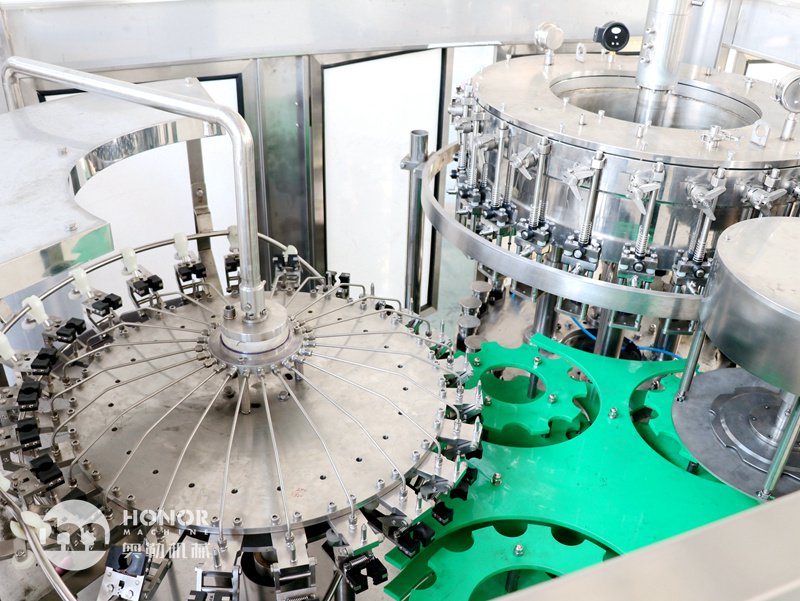

This machine is beer filling machine, with washing,filling and capping parts. It adopts advanced international technology to design, appearance is nice, operation and maintenance is convenient, it's high degree of automation, so it's good machine for midd

This machine is beer filling machine, with washing,filling and capping parts.

It adopts advanced international technology to design, appearance is nice, operation and maintenance is convenient,

it's high degree of automation, so it's good machine for middle and small capacity beer manufacturer.

Structural Features:

1, The rinsing machine using high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal

of the glass bottles. The nozzle is a plum-like structure can wash every corner of the sidewall and bottom to make the

bottle clean.

2, Filling machine with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support

floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

3, Using high-precision mechanical filling valve, with cylinder liquid level and the back pressure controlled by a variable

signal proportional. Fast, stable, accurate, to be vacuum one at a time.

4, Stainless steel plunger and mechanical stirring gland-type magnetic reasonable cap to ensure that the gland is healthy

and reliable. Hopper and the cap taking- cover, capping transmitted by magnetic. The capping is reliable and automatic

unloading, reducing the rate of broken bottles.

5, Before the capping, use hot water bubble set to displace bottlenecks air, ensuring the oxygen content of less than

0.15mg / L.

6, Filling machines includes broken bottle automatically stopping valve, broken bottle washing, and foam automatically

exhausting device.

7, With perfect CIP cleaning function, and capable of rinsing filling pipes with acid, lye liquid and hot water.

8,All the materials in contact with the valves, tanks, pipes are made of stainless steel 304 materials, inside and outside

the wall of mirror-polished, ensuring it is healthy.

9, Manually dry oil lubrication system to make sure equipment maintenance is more convenient.

10, The whole operation adopts advanced man-machine interface, PLC control, frequency conversion stepless speed

regulation and other automatic control technology, with no bottle no open valves, no stamps; no cap no operation, and

other security protection.

Filling process:

Step1: Vacuum valve ,it will take the oxygen out of the bottle first ,

Step2: Filling CO2 to clean the bottle to remove all oxygen

Step3: Vacuum valve : to exhaust the Co2

Step3: Fill CO2 ,And when the pressur in the bottle equals to the filling tank ,it will start to fill beer

Step4: Between filling part with capping part ,there is a foam device to inject the water into the bottle ,to confirm no

oxygen into the bottle.

Main parts list:

Item | Parts Name | Brand | Brand |

1 | PLC | SIEMENS | Germany |

2 | Inverter | ||

3 | Touch Screen | ||

4 | Switch | ||

5 | Contactor | ||

6 | Relayer | ||

7 | Solenoid Valve | AIRTAC | Taiwan |

8 | Drive motor | FEITUO | Swiss |

9 | Reducer | CNP | China |

10 | Water Pump | SKF | China |

11 | Main Bearing | AUTONICS | Sweden |

12 | Sensor | AIRTAC | Korea |

13 | Air component | ABB | Taiwan |

Detailed Pictures:

|  |

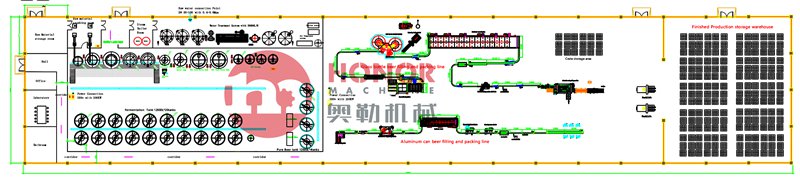

Model | BCGF14-12-4 | BCGF18-18-6 | BCGF24-24-8 | BCGF32-32-10 |

Capacity(500ml/bottle/h) | 1000-2000 | 2000-4000 | 4000-6000 | 6000-8000 |

Total power(kw) | 3.5 | 3.8 | 5.8 | 7.8 |

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

A2:Our Factory is located in Zhangjiagang City, it is very near to Shanghai and Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

A3:Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

A4:We offer you high quality machines with 2 years guarantee and supply life-long technical support. We Warmly Welcome Customers All Over The World To Our Company If You Have Interests In Our Products. Please Contact Us If You Have Any Problems.You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.