-

+86-13584422722

+86-13584422722

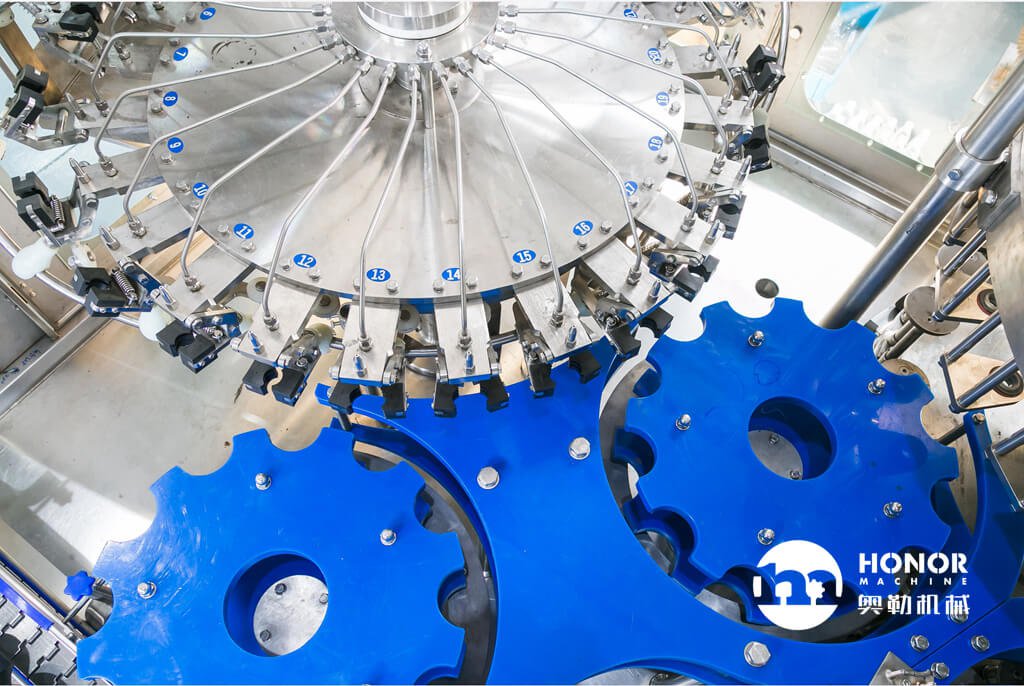

The honor machine offers a wide range of industry experience and liquid filling capabilities while bringing the lower ownership costs for customers. Therefore, the old customers in Kenya once again chose Honor's 24-head white wine filling machine.

A 24 head filling machine is the rotary quantitative filling machine, high automation, and large production capacity. The filling process is the perfect combination of photics and pneumatics, mechanism, electricity, which performance accomplish the international advanced technology. 24 head filling machine adopts advanced electrical and mechanical integration technology. By modifying parameters in the touch screen, any specification can be changed. Each kind of package specification is saved in the computer memory which saves time for the next adjustment. Each part of the mechanical drive is saved by mechanical and electrical integration during the running cycle. If anything goes wrong during the process the machine stops automatically and alarm and touch screen show where the problem is. It is an environment-friendly product because of its watertight and pneumatic protection. Open gear combined gearbox transmission, with on-off device, frequency conversion velocity modulation device extends the speed modulating scope. There is a self-oil lubrication device, the lubrication points could be lubricated regularly in time, so this machine with high efficiency, low noise, and long using life.

1) The main operation of the machine is wine and sauce filling.

2) Rinsing, filling, and capping are the main functions of a machine.

3) There is an automatic process and suitable for aluminum steel proof caps for filling vodka, wine, etc and glass bottles.

4) Various types of bottles can be filled as the machine can adjust.

5) The machine has a very fast and stable filling process due to negative pressure filling operation is adopted, that is why as compared to other machines with the same capacity it has more capacity and benefits.

6) The advanced OMRON programmable controller (PLC) is adopted to control the machine running automatically, and bottle input conveyor adopts transducer with speed adjustable, and bottle output conveyor adopts speed adjustable motor;

7) The bottle runs steadily and reliably with the help of the transducer of the main machine.

8) Every part of the machine is inspected to run by a photoelectric detector make it convenient to operate with high automation.

9) For beverage makers, the machine is an idea of preferred equipment.

The product has a 1-year warranty under stable voltage and long time technology will be supplied to the customer in Kenya. The company can send his engineer to install and debug machines. The engineer's expenses will be charged to you. The company can also provide a supply training process for the buyer’s engineers who come to China and the customer can fit and debug machine by themselves. No matter what it is the company policy to provide sincerely what you want and what you need.